Go Farther Using Fiberglass Electrical Conduit

ADVANTAGES

- Fiberglass has a lower coeficient of friction

- Easy to cut. Faster to install.

- Light to work with.

- No chlorine, halogen or other toxic materials

- Temp range -40F to +230F

- High temperature rating results in no cable fusion

- Impervious to a wide spectrum of chemicals and fuels

- Non-Conductive

- Non-Corrosive

- Complete line of fittings

BELOW GROUND FIBERGLASS CONDUIT

- Tri-Seal joint is watertight up to 50 Psi

- Superior impact & crush resistance

- Rot & rodent proof

- Highest strength to weight ratio of any conduit

- Suitable for Direct Burial (DB) and/or Encased Burial (EB)

- Available in 3/4 inch (19 mm) through 8 inch (203 mm) diameters

ABOVE GROUND FIBERGLASS CONDUIT

- Fire resistant and non-toxic

- Thermal expansion rate is similar to RMC

- Suitable for indoor use (non-hazardous locations)

- Field bendable with hot box

- Special colors available upon request

- Quick push fit Tri-Seal (1 piece urethane gasket )

- Tri-Seal joint is watertight up to 50 Psi

- No adhesive or threading

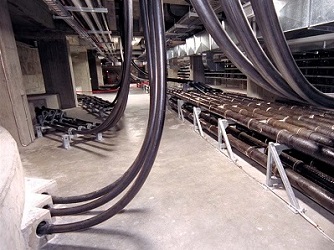

LOW SMOKE/ HIGH TEMP FIBERGLASS CONDUIT

- For tunnels, subways & confined areas (vent shaft, steam tunnels)

- Emits no toxins or halogen (SMP 800C)

- Thermal expansion rate is lower than RMC

- Outstanding fire resistance (ASTM E84)

- Suitable for use indoors

- Bell and Spigot joint for fast, easy adhesive assembly

- No threading or masking of joints required

- Class 1 fire rated (ASTM E84), NFPA 130 compliant, NFPA 502 compliant, FT4 rated (CSA)

UNDER WATER FIBERGLASS CONDUIT

- Flexible & easy installation

- Lowest installation cost

- Can be installed year round

- Excellent impact and compressive resistance

- Complete line of conduit from 2 inch-6 inch ID

- All joints are spliced in continuous length on shore and pulled at once as a complete assembly

HAZARDOUS LOCATION CONDUIT

- Small caliber, low velocity, projectile resistant

- Highest strength to weight ratio of any conduit system

- Superior load bearing

- Lightweight: A 19.68 ft. section of 4″ conduit weighs less than 45 lbs.

- Fewer expensive hangers supports and inserts on bridge installations

- High flexural strength

- Superior UV and weathering characteristics

- Suitable for physical damage locations, above ground and bridge applications

- UL2515/CSA C22.2 No.2515